Streamline Your Warehouse Inventory Management Process with Practical Tips

Introduction to Warehouse Inventory Management

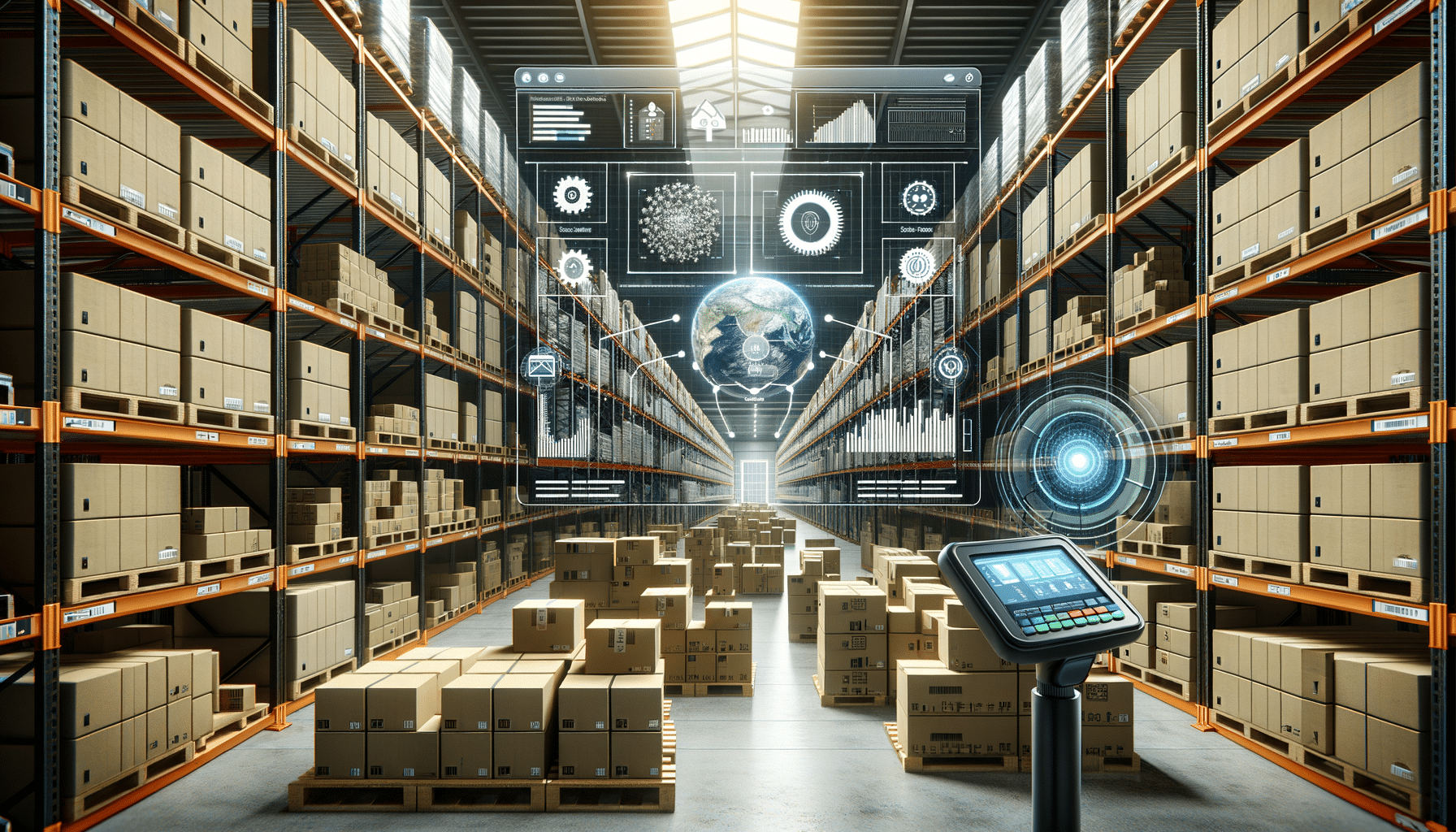

Warehouse inventory management is a critical component of any business that deals with physical products. It involves the systematic control and oversight of goods stored in a warehouse to ensure that inventory levels are maintained at optimal levels. Effective inventory management helps businesses reduce costs, improve cash flow, and enhance customer satisfaction. In today’s competitive market, mastering warehouse inventory management can provide a significant edge.

Understanding the Basics of Inventory Management

At its core, inventory management involves tracking and controlling stock levels to prevent overstocking or stockouts. The process includes several key activities such as ordering, storing, and using inventory. Successful inventory management requires a balance between supply and demand, ensuring that the right amount of stock is available at the right time.

Businesses often use inventory management systems to automate and streamline these processes. These systems can track inventory in real-time, providing valuable insights into stock levels, turnover rates, and other critical metrics. By leveraging technology, companies can enhance accuracy and efficiency in their inventory management practices.

- Real-time inventory tracking

- Automated reorder alerts

- Comprehensive reporting and analytics

Challenges in Warehouse Inventory Management

Despite its importance, warehouse inventory management comes with its own set of challenges. One of the most common issues is inaccurate inventory records, which can lead to stock discrepancies and impact order fulfillment. Additionally, managing a large volume of stock can be overwhelming without the right tools and processes in place.

Another challenge is dealing with seasonal demand fluctuations. Businesses must anticipate changes in demand and adjust their inventory levels accordingly. Failure to do so can result in excess stock or shortages, both of which can have financial implications.

- Inaccurate inventory records

- Handling seasonal demand fluctuations

- Managing large volumes of stock

Strategies for Effective Inventory Management

To overcome these challenges, businesses can implement several strategies to improve their inventory management practices. One approach is to adopt a just-in-time (JIT) inventory system, which reduces the need for large stockpiles by ordering goods only as they are needed. This method can help minimize storage costs and reduce waste.

Another effective strategy is to classify inventory using the ABC analysis method. This technique involves categorizing inventory into three groups based on value and turnover rate, allowing businesses to prioritize their resources on the most critical items. Additionally, regular audits and cycle counts can help maintain accurate inventory records and identify discrepancies early.

- Just-in-time (JIT) inventory system

- ABC analysis for inventory classification

- Regular audits and cycle counts

Leveraging Technology in Inventory Management

Technology plays a pivotal role in modern warehouse inventory management. Advanced inventory management software can integrate with other business systems, providing a comprehensive view of operations and facilitating data-driven decision-making. Features such as barcode scanning and RFID technology can further enhance accuracy and efficiency in inventory tracking.

Moreover, the use of artificial intelligence and machine learning can help predict demand patterns and optimize inventory levels. By analyzing historical data, these technologies can provide actionable insights that enable businesses to make informed decisions about stock levels and order quantities.

- Inventory management software integration

- Barcode scanning and RFID technology

- AI and machine learning for demand forecasting

Conclusion: The Future of Warehouse Inventory Management

As businesses continue to evolve, so too will the landscape of warehouse inventory management. Embracing new technologies and strategies will be crucial for staying competitive in the market. By focusing on accuracy, efficiency, and adaptability, companies can optimize their inventory management processes and drive long-term success.

In conclusion, effective warehouse inventory management is essential for any business that deals with physical products. By understanding the challenges and implementing strategic solutions, businesses can enhance their inventory management practices and achieve operational excellence.