Streamline Your Warehouse Operations with Our Stock Management System

The Importance of Warehouse Inventory Management

Warehouse inventory management is the backbone of any successful supply chain. Efficient management ensures that products are stored, tracked, and delivered in a timely manner, minimizing costs and maximizing customer satisfaction. Proper inventory management helps in reducing overstocking and stockouts, which can lead to financial losses and dissatisfied customers. By maintaining a balanced inventory, businesses can improve cash flow and invest in other areas of growth. Additionally, well-organized warehouse inventory can enhance productivity by reducing the time spent searching for items, thus allowing employees to focus on more value-added tasks.

Furthermore, accurate inventory management is crucial for maintaining a competitive edge. In today’s fast-paced market, customers expect quick delivery times and accurate order fulfillment. A well-managed inventory system ensures that businesses can meet these expectations, leading to repeat business and customer loyalty. Moreover, with the rise of e-commerce, warehouses are under increased pressure to handle larger volumes of orders efficiently. Implementing a robust inventory management system can help businesses scale their operations and meet the growing demands of the market.

Key Components of an Effective Inventory System

An effective inventory system is composed of several key components that work together to ensure smooth operations. These components include inventory tracking, demand forecasting, and stock replenishment. Inventory tracking involves monitoring the movement of goods within the warehouse, ensuring that every item is accounted for. This can be achieved through barcoding or RFID technology, which provides real-time data on inventory levels and locations.

Demand forecasting is another critical component, as it helps businesses predict future sales and adjust their inventory levels accordingly. By analyzing historical sales data and market trends, businesses can anticipate changes in demand and prepare their inventory to meet these fluctuations. This proactive approach reduces the risk of overstocking or stockouts, ensuring that customers receive their orders on time.

Stock replenishment is the process of restocking items to maintain optimal inventory levels. This involves setting reorder points and safety stock levels to ensure that inventory is replenished before it reaches critical levels. An effective replenishment strategy minimizes the risk of stockouts and ensures that the warehouse operates efficiently.

Benefits of a Stock Management System

Implementing a stock management system offers numerous benefits to warehouse operations. One of the primary advantages is improved accuracy in inventory tracking. With automated systems, businesses can reduce human error and ensure that inventory records are up-to-date. This accuracy leads to better decision-making and more efficient operations.

Another benefit is increased efficiency in order fulfillment. A stock management system streamlines the picking and packing process, reducing the time it takes to fulfill orders. This efficiency translates to faster delivery times and improved customer satisfaction. Additionally, a stock management system can optimize warehouse space utilization by providing insights into inventory turnover rates and identifying slow-moving items.

Cost savings are also a significant benefit of a stock management system. By reducing excess inventory and minimizing stockouts, businesses can lower their carrying costs and improve their bottom line. Furthermore, automated systems can reduce labor costs by eliminating manual inventory checks and streamlining warehouse operations.

Challenges in Warehouse Inventory Management

Despite the advantages, managing warehouse inventory comes with its own set of challenges. One common issue is inaccurate inventory data, which can lead to stock discrepancies and affect order fulfillment. To address this, businesses must invest in reliable inventory tracking technology and regularly audit their inventory records.

Another challenge is managing seasonal demand fluctuations. Businesses must be able to adjust their inventory levels to accommodate changes in demand without overstocking or running out of stock. This requires accurate demand forecasting and a flexible inventory management system that can adapt to changing market conditions.

Warehouse layout and organization also pose challenges, as inefficient layouts can lead to longer picking times and decreased productivity. To optimize warehouse operations, businesses should regularly review their layout and implement strategies to improve workflow and reduce congestion.

Future Trends in Inventory Management

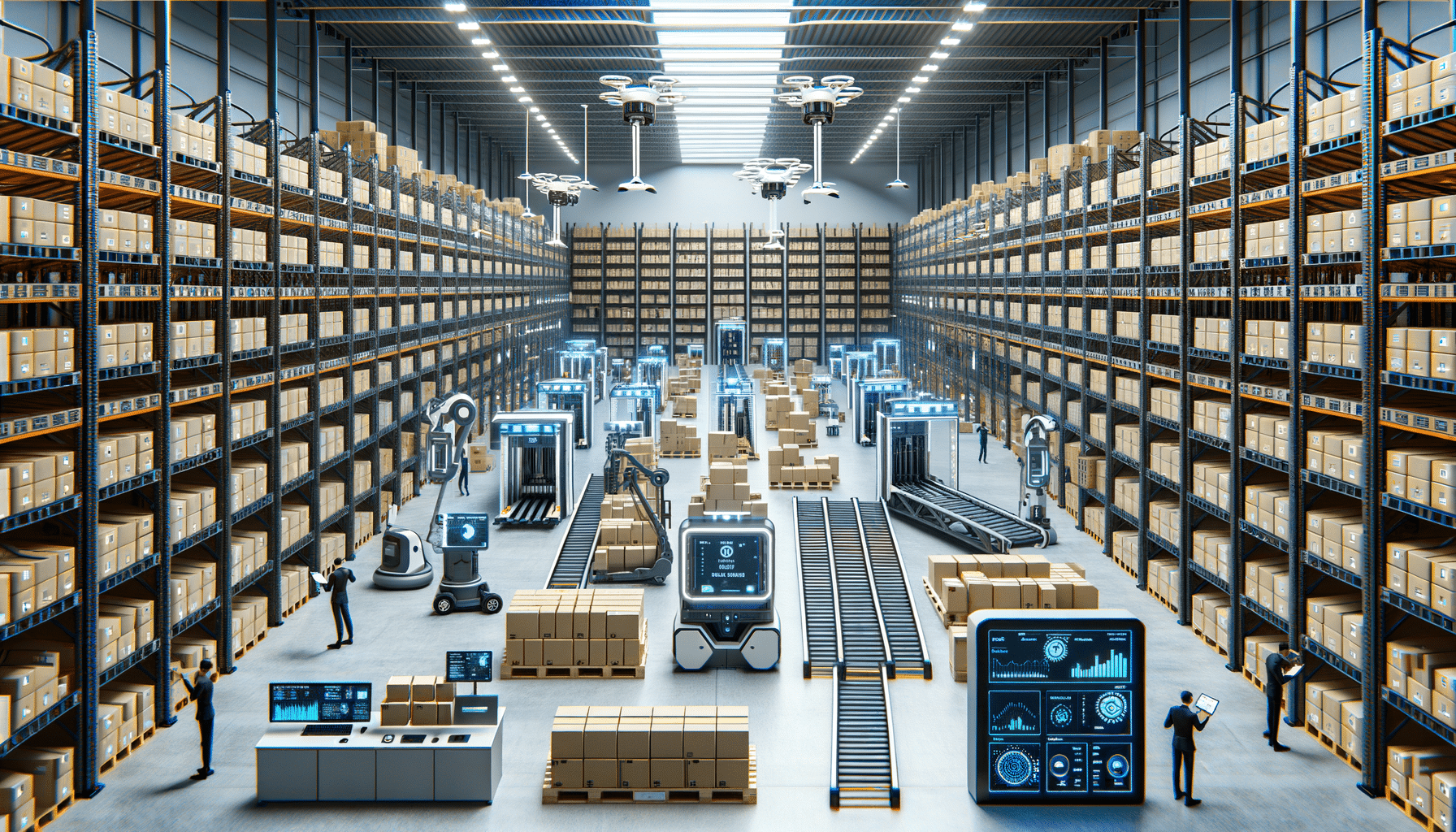

The future of inventory management is being shaped by technological advancements and changing consumer expectations. One emerging trend is the use of artificial intelligence (AI) and machine learning to improve demand forecasting and inventory optimization. These technologies can analyze vast amounts of data to identify patterns and predict future demand more accurately than traditional methods.

Another trend is the adoption of Internet of Things (IoT) devices in warehouses. IoT devices can provide real-time data on inventory levels, environmental conditions, and equipment performance, enabling businesses to make informed decisions and improve operational efficiency. Additionally, the use of drones and autonomous vehicles for inventory management is gaining traction, offering faster and more accurate inventory checks.

Sustainability is also becoming a key focus in inventory management. Businesses are increasingly looking for ways to reduce waste and minimize their environmental impact. This includes optimizing inventory levels to reduce excess stock and implementing sustainable packaging solutions.